'Recognizing the need is the primary condition for design.'

Milton Glaser

About - Project 2021 Protect

Mission statement:

Project 2020 Protect aims to work towards resolving the immediate issues of protecting and supporting those who are in need of easily manufacturable devices that can reliably protect them from infection and sustain respiritory function in locations where electrical supply is unavailable. The project is a non-profit venture.

Design Brief

There is an urgent need for a hand or mechanically operated respiritory device that can be easily manufactured using 3D print technology and used reliably with little or no training to support the breathing of people in need of respiritory support.

Idealy the design may even be simple enough for the patient to operate independantly where possible.

The design of the device should be adaptable enough to be capable of operating using different sized breathing bottles, e.g. for adults, children and babies. (Details of the dimensions of the adut breathing bottle can be found below.)

Where we are now with the design...

Adult size bottle dimensions (Approximate - CAD drawing to be added in the near future)

Current status of operational design features:

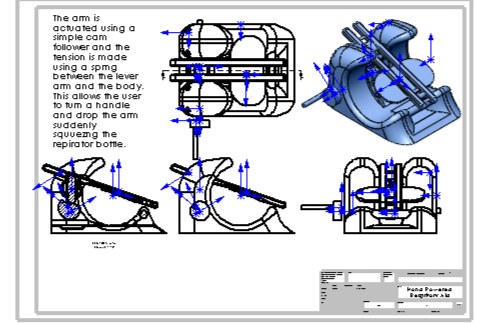

Using a nautilus shaped cam and a cam following lifting pin (set in front of the arm fulcrum) the design so far utilises the cam follower (you can see on the sectional model) to lift the pressure arm upwards against a spung mechanisim or spring (shown in video of micro model) which then releases downwards as it slips over the nautilus shaped cam activating the expulsion of air from the bottle.

The design has initially been drawn to be operated on a turn handle but this mechanisim could be improved upon or replaced with a different soluton if it were easier to manufacture and/or assemble or reused commonly available materials or existing objects.

To be viable for 3D printing the mechanical parts will need increasing dimensionally and/or other strength added through design. These parts will take repeated compressional and torsional force and will need to be printed in carbon fibre or nylon.

NB. As we were awaiting the arrival of the breathing bottle at the time of initial design, dimensions were estimated and the design features will need reworking dimensionally and mechanically to be able to fix a viable design solution, no mechanical calculations have been made to date.

Initlal Orthographic drawing with X plane sectonal view. (No dimensions)

Micro size model of main body and lifting arm design and position.

Models of main parts below (connector pins not shown)

What you can do to help...

All completed project work to be submitted via. email to jkupper@ESCG.ac.uk

Project task list to be accomplished:

1: Analyse the project brief and status at the present time.

2: Identify opportunities for development and improvement.

3: Research and identify dimensional and materials information to create a list of specifc constraints that will be determined by the nature of the product requirements set out in the brief. (Identify any areas that appear unclear or in need of further detail in the brief and what questions you need to ask to find out that detail).

3.5: Start to write up a specification at this point (there will be areas that you will pin down in 4.5 so just fill out what you can for now).

4: Having pinned down the dimensional information e.g. the sizes of different available bottle systems etc. Start to draw up a range of designs that could potentially become viable solutions. Develop one or two designs further including annotation and dimensional information.

4.5: Revisit your specification and complete it adding all of the design specifics you consider to be relevent.

5: Using Fusion 360 (Free) or Solidworks (If you have access to it) or another CAD package model the design as best you can. (If you do not have an available CAD package then use your hand drawing and annotations to convey your idea, perhaps one of your collegues can help you draw your idea up on CAD remotely?)

6: Having considered possible materials and/or brought in components to be utilised within the design develop a production plan and bill of materials including an estimated activity based costing.

7: Present your final design idea as a 3D model, a 2D Orthographic production drawing (pencil or digital), a bill of materials, a preliminary production plan and a written justification on how you have made sure that your design fulfils the intended function and criteria of the brief while remaining to be designed in consideration of reducing environmental impact from production to end of life treatment.