'Recognizing the need is the primary condition for design.'

Milton Glaser

Cooling systems

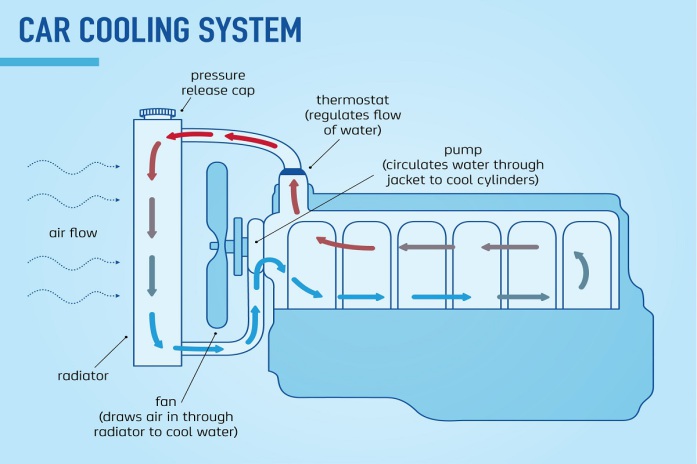

A cooling system in an automotive application is most often used to keep the temprature of the engine / motor at a level where it is optimal for preformance.

Cooling systems stop overheating and they also monitor the car if it falls below safe opperating temprature.

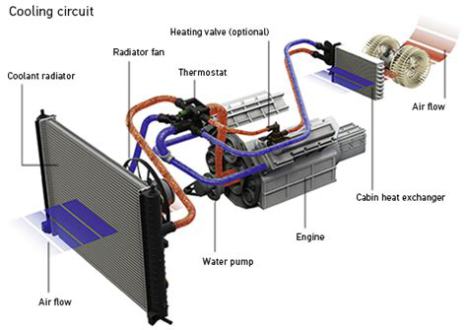

The image on the right shows the main components and the standard layout for a automotive application.

The diagram in this section gives a short description of the function of the main parts of a cooling system.

Task 1: Cooling system worksheet

Download this worksheet and complete the tasks to reinforce your learning about cooling systems

Cooling system worksheet 1.jpg

JPG image [113.0 KB]

Task 2: Watch the short video below and then discuss any points you are still unclear about with your collegues or tutor

Car air conditioning systems (A/C)

Air conditioning has two main purposes:

- Cools the air entering the passenger compartment

- Removes the moisture from the air so it feels more comfortable inside the vehicle.

Download and complete the worksheet on automotive A/C systems

AC workshet.jpg

JPG image [113.9 KB]

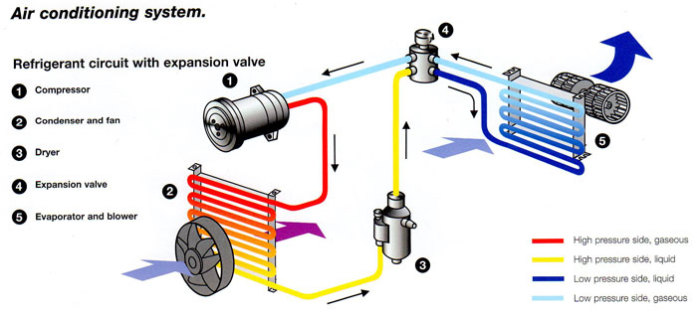

Process:

The air conditioning system is pressurized by a gas known as refrigerant. Each vehicle specifies how much gas is used to fill the system so it's important to check the ammount before filling an A/C system.

1: The compressor compresses the refrigerant from a gas turning it into a fluid. This fluid is then pushed through a refrigerant line under high pressure, this is called the high side.

2: The condenser is next inline in the system: The refrigerant flows through a grid similar to a radiator. Air passes through the condenser and removes the heat from the refrigerant.

The refrigerant then moves on next to the expansion valve this reduces the pressure in the line and the refrigerant turns back to gas.

3: The receiver drier / accumulator. Here, a desiccant (drying agent) in the receiver drier removes moisture that is carried in with the refrigerant in gas form.

4: The cooler dried refrigerant passes into the evaporator, still in its gaseous form. The evaporator is the only part of the air conditioning system that is in the passenger compartment. Air blows through the evaporator core, the heat is removed from the air and transferred into the refrigerant, leaving cooler air exiting past the evaporator.

The refrigerant passes through to the compressor again. The process continues repeatedly.