'Recognizing the need is the primary condition for design.'

Milton Glaser

Gears and Ratios

Gears are an essential part of most mechanical devices.

Gears fit (mesh) togeather by interlocking teeth.

The size of the diameter of the gear cog is directly related to the number of teeth it has.

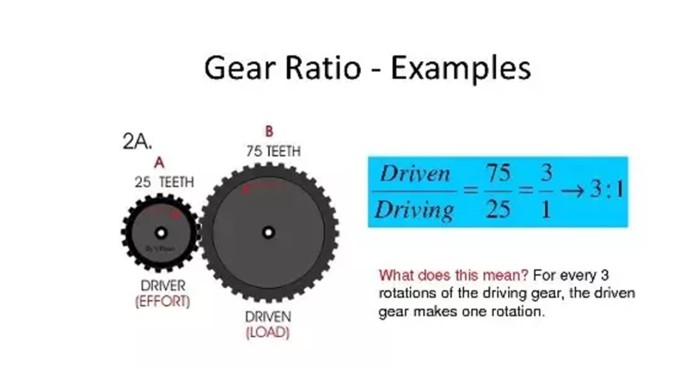

Knowing the number of teeth of two meshed gears allows us to be able to work out the power rating of the gear system or gear train.

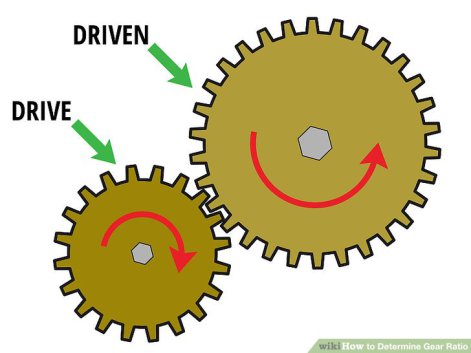

Driving and Driven Gears:

Principals of gear direction:

Adobe Acrobat document [93.9 KB]

Calculating gear ratios:

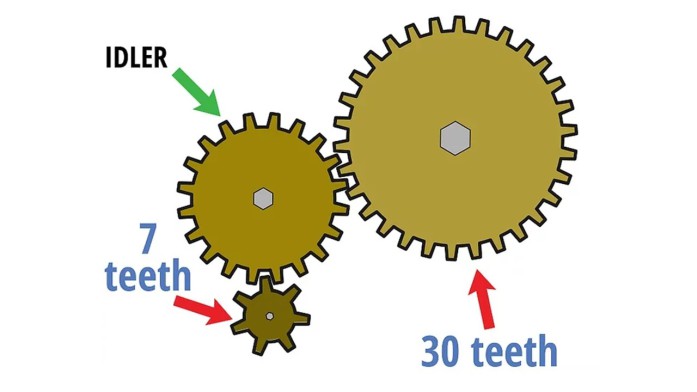

Idler gear:

Idler gears are used when you need to transfer power accross a larger distance or make a change in rotational direction between the input (driving) gear and the output (driven) gear.

Idle gears do not add more power or chage the ratio of the driven to driving gears in any geared system.

They are called idle because they neither add or take away any mechanical advantage.