'Recognizing the need is the primary condition for design.'

Milton Glaser

Dfferential gears:

Differential gears are used in the back axel of a vehicle.

Using a differential gear connected to the drive wheels means that the wheels themselves can move independantly of each other.

This allows the vehicle to manage different wheel speeds without locking up the axel and causing the car to slide or flip over.

Types of differential gearing:

- Open Differential

- Locked Differential

- Viscous Limited Slip Differential

- Mechanical Clutch-Type LSD (Including eLSD)

- Torsen & Helical Differential

- Torque Vectoring Differential

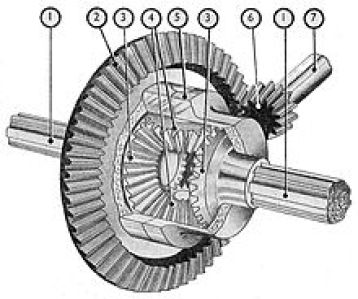

Parts of a standard (Open) differential gear system:

1: Axel shafts

2: Ring gear

3: Differential side gear

4: Differential pinion

5: Housing

6: Drive pinion

7: Drive shaft

Task 1: Download the worksheet below and label the parts of the standard differential gear system.

Write a short description of how the differential works.

Locking Differential:

Task 2: Download and complete the worksing sheet on locking differentials

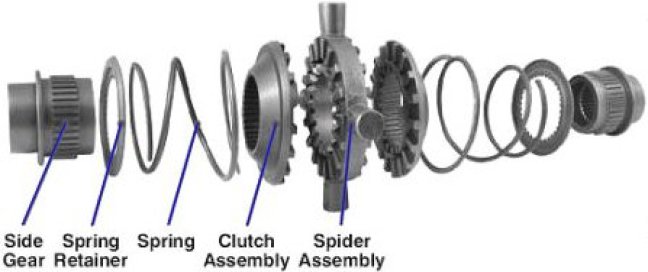

Viscious Limited Slip Differential - VLSD

This style limited-slip differential works by using a gerotor pump to hydraulically compress a clutch to transfer torque to the wheel that is rotating slower.

The gerotor pump uses the differential carrier or cage to drive the outer rotor of the pump and one axle shaft to drive the inner rotor.

When there is a difference between the left and right wheels' speed, the pump pressurizes the hydraulic fluid causing the clutch to compress. This causes the torque to be transferred to the wheel that is rotating slower.

These pump-based systems have lower and upper limits on applied pressure which allows the differential to work like a conventional or open differential until there is a significant speed difference between the right and left wheel, and internal damping to avoid hysteresis.

The newest gerotor pump based system has computer regulated output for more versatility and no oscillation.