'Recognizing the need is the primary condition for design.'

Milton Glaser

Welding Technology

This section of the website covers a number of essential elements that need to be considered and understood inorder to complete your welding module.

LA A - Properties and behaviours of welded materials

LA B - Examine weldable materials and thier behaviour during the welding process

LA C - Carry out practical welding skills safety to join metallic materials togeather

Please review this document and use it as an example of what is expected for a level 3 Distinction grade

Welding assignment Examplar.pdf

Adobe Acrobat document [579.8 KB]

Destructive and non-destructive weld testing

When testing welded materials for defects there are two main types of test that can be carried out. Destructive (breaking the weld appart) and Non-Destructive (not breaking the weld appart)

Below is a short description of some of the available techniques.

Learning aim A assignment brief

Microsoft Word document [78.2 KB]

Above are two examples of welding applications for you to use in your writeup for LA A.

1: Tig welded titanium bike frame

2: Mig welded lap joins for a leg housing / retainer

Student work examplar LA A Unit 13

Microsoft Word document [69.0 KB]

Learning aim B assignment brief

Microsoft Word document [77.6 KB]

Student work examplar LA B Unit 13

Common defects in welding:

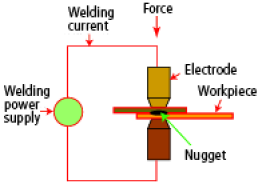

Resistance welding

Resistance welding is conducted as follows:

Apply force and current through electrodes in contact with metal parts to be welded; resistance heat is generated at the interface of metal parts and makes a nugget, resulting in melt joint.

Though a large current flows, there is no danger of an electric shock because only low voltage is impressed.

- BS1140: - British Standard specification for Resistance spot welding of uncoated and coated low carbon steel.

- ISO 10447: - Welding - Peel and chisel testing of resistance spot, projection and seam welds.

Microsoft Word document [13.4 KB]

Types of welding

Microsoft Word document [33.7 KB]

Microsoft Word document [82.4 KB]

Below is a short description for each type of welding used in industry

Learning aim C assignment brief

Microsoft Word document [78.7 KB]

Student examplars LA C Unit 13

Below are a range of supporting documents to help you complete your welding assignments.

Please download this and use it to find out more about safety when Arc welding

Welding safety.pdf

Adobe Acrobat document [5.2 MB]

Download and review this document for the main points re: safety when Arc welding

safety-arcwelding.ppt

Microsoft Power Point presentation [682.0 KB]

Information containing types of power supply needed for types of welding

Welding power supplies.pptx

Microsoft Power Point presentation [236.9 KB]

When referring to this guide please be aware that your machine may be of a different type so pay attention to any differences the specific machine you are working on may have

ESAB Buddy 160 TIG (MMA) Get Started.doc[...]

Microsoft Word document [1'018.8 KB]

When referring to this guide please be ware that your machine may be different of a different type so pay attention to any differences the specific machine you are working on may have

ESAB Caddy 160i MIG Get Started.docx

Microsoft Word document [1.0 MB]

Please use this to find out more about the issues and effects of welding on steels

Arc welding steels metallurgy PWHT etc.p[...]

Adobe Acrobat document [18.0 MB]