'Recognizing the need is the primary condition for design.'

Milton Glaser

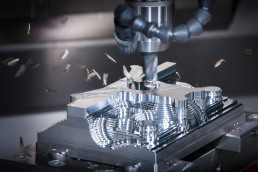

U41 Secondary Machining Processes

During this unit you will learn about secondary machining processes. You will also be expected to produce machined parts using two or three industrial processes. These may vary depending on your institutions access to machinery but in most cases these are a vertical mill, a centre lathe and a sheering or grinding / buffing tool.

Learning Aim A

UNIT 41 A Assignment Brief 2021.docx

Microsoft Word document [819.4 KB]

Machine diagrams: Centre lathe, Vertical Mill, Pillar Drill.

Use the diagrams below to help you in identifing the parts of each machine, use the correct termonology when writing up your work.

Adobe Acrobat document [2.0 MB]

Adobe Acrobat document [440.4 KB]

Adobe Acrobat document [1.2 MB]

Adobe Acrobat document [278.5 KB]

Tooling diagrams and info: Centre lathe, Vertical Mill, Pillar Drill.

Use the diagrams below to help you in identifing the tools and processes that each machine employs and make sure to use the correct termonology when writing up your work.

Surface finish information:

Surface finish and machining symbols (what they mean) presentation:

Unit 41 - Supporting files, H&S, Machine Manuals, Case studies of processes.

Below are supporting files to help you complete all learning aims for U41

Machining H&S files:

Adobe Acrobat document [2.4 MB]

Adobe Acrobat document [1.8 MB]

Adobe Acrobat document [4.4 MB]

Adobe Acrobat document [36.7 KB]

Machining manual files:

Adobe Acrobat document [35.8 KB]

Adobe Acrobat document [209.8 KB]

Adobe Acrobat document [3.0 MB]

COSSH:

Adobe Acrobat document [918.6 KB]

Adobe Acrobat document [212.6 KB]

Case studies:

Adobe Acrobat document [103.9 KB]

Adobe Acrobat document [1'005.1 KB]

U41 - Learning Aim B & C

Learning aim B & C require you to produce evidence of setting up and using secondary machining processes researched in assignment 1. You will accurately produce three machined components / parts safely.

UNIT 41 BC Assignment Brief 2018.docx

Microsoft Word document [75.5 KB]

|

To evidence your maching work for LA B&C you have to produce a report/logbook that: a) shows how set up each machine b) use of the machine c) parameters used e.g. speeds Your report should also include: · risk assessments for each machine used · the finished components/products · annotated photographs and drawings · complete quality control documents |

Scribe tool and Screwdriver drawings for production:

PDF File [143.8 KB]

PDF File [299.2 KB]

Adobe Acrobat document [32.8 KB]

Technical drawings for Screw Jack production:

U41 - Learning Aim D

Unit 41 D-Manufacturing-Secondary-Machin[...]

Microsoft Word document [76.0 KB]

To complete U41 Assignment D:

You will need to collate your evidence from Assignment 2.

You should then review and reflect on the activities that you completed and behaviours that you showed when setting-up and using secondary machining processes to produce a component.

There is more specific guidance on the range of activities and topics that you will have to assess in LA - D found the assignment sheet above and the slides below, so make sure that you check the assignment sheet regularly when writing up LA - D.